The Preformed Suspension Clamp is the connecting hardware of ADSS cable hang in transmission line pole (tower). It can reduce static stress at the support point and increase ant-vibration ability of ADSS cables, and cushioned against the dynamic stress of aeolian vibration

Description:

Suspension clamp for ADSS cable protects the conductors and other devices from aerial vibrations and swinging caused by strong winds and storms. The clamps are made from galvanized steel and aluminum alloy, which helps them to resist corrosion caused by the different weather conditions in the environment. The resistance offered helps to increase the durability of the suspension clamps for overhead lines which in turn helps to reduce the repair and maintenance life costs.

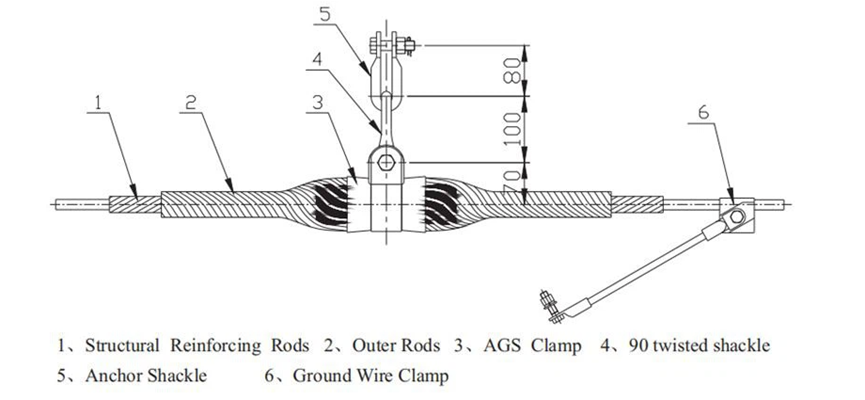

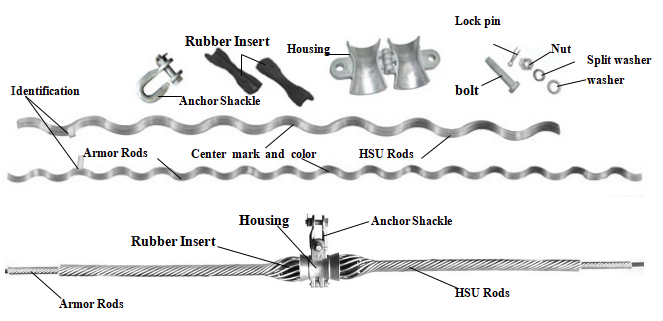

Structure:

● Housing--- It is made of corrosion resistance cast aluminum alloy, which is stable, better anticorrosive in aero and mechanical performance.

● Rubber Insert--- It consists of high-class rubber and center reinforcing assembly, rubber insert is with ozone resistance, chemical resistances, weather resistance performance, with high and low temperature performance, high strength and elasticity, small compression deformation.

● Bolt, Flat Washer, Spring Washer, Nut, Split Lock, Shackle--- Standard Parts of Electric Power.

● Inner Preformed Rods---According to the mechanical performance and chemical composition to custom-made the aluminum alloy wire, with high tensile strength, hardness strength and excellent elasticity and strong rust resistance , it can be used for a long time in the bad weather condition.

Installation:

l Mark the cable at the center of the suspension attachment point with a plumb string.

l Center the top and bottom halves with the center mark in Step 1 and secure with a thin layer of tape.

l Center the Protection Rod on the top Insert with the center mark aligned. Make sure the Rod follows the curvature of the Insert. Apply 2 or 3 complete wraps beyond each end of the Insert. There should be no space between the Rod and Insert. Do not wrap rod around Insert.(Protection Rod cannot intersect Cable)

l Repeat Step3 with Rod centered under the bottom half of the Insert.

l Apply all other Rods in the same method. Make sure the Rods are evently spaced and are not crossed.

l Using firm hand pressure only, wrap the ends of the Rods in place. Do not use any tool which could scar or damage the cable.