The galvanized steel wire for armoring is made of high-quality carbon steel wire rods through a series of processes such as heat treatment, shelling, washing, pickling, washing, solvent treatment, drying, hot-dip galvanizing, and post-treatment, etc.

It is widely used in power cable, telephone cable and telecommunication cable.

Description:

The galvanized steel wire for armoring is made of high-quality carbon steel wire rods through a series of processes such as heat treatment, shelling, washing, pickling, washing, solvent treatment, drying, hot-dip galvanizing, and post-treatment, etc.

Under the condition of high strength of the steel wire, the corrosion resistance of galvanized steel wire for armoring is greatly improved by the process of surface galvanizing. Armoring by steel wire is one of the commonly used types in armored cables, which can increase the axial tensile strength of the cable, prevent mouse bites, and resist external low-frequency interference. It can protect the cable, extend the service life and improve the transmission performance of the cable.

Characteristics:

1) The surface is smooth and clean, free of defects such as cracks, slubs, thorns, corrosion, bends and scars, etc.

2) The zinc layer is uniform, continuous, bright and does not fall off.

3) The appearance is round with stable size, high tensile strength.

It can meet the requirements of BS EN10257-1, BS EN10244-2, GB/T3082 and other standards.

Technical Specification:

| Nominal diameter (mm) | Tensile strengt(N/mm2) | Min. breaking elongation(%)gauge length (250mm) | Torsion test | Min. weight of zinc layer (g/m2) | |

| Times / 360° | Gauge length (mm) | ||||

| 0.8 | 340~500 | 7.5 | ≥30 | 75 | 145 |

| 0.9 | 7.5 | ≥24 | 75 | 155 | |

| 1.25 | 10 | ≥22 | 75 | 180 | |

| 1.6 | 10 | ≥37 | 150 | 195 | |

| 2 | 10 | ≥30 | 150 | 215 | |

| 2.5 | 10 | ≥24 | 150 | 245 | |

| 3.15 | 10 | ≥19 | 150 | 255 | |

| 4 | 10 | ≥15 | 150 | 275 | |

| Note: More specifications, please contact our sales staff. | |||||

Process flow

Steel Wire Rod Drawing→Drawing To 2.0mm→Coal Furnace Annealing→Water Tank Drawing→Electric Furnace Annealing→Galvanization→Packing

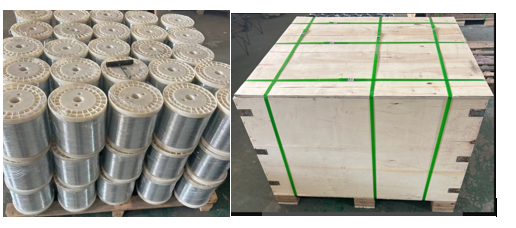

Packaging: